Agriculture Machinery Parts

Agriculture Machinery Parts

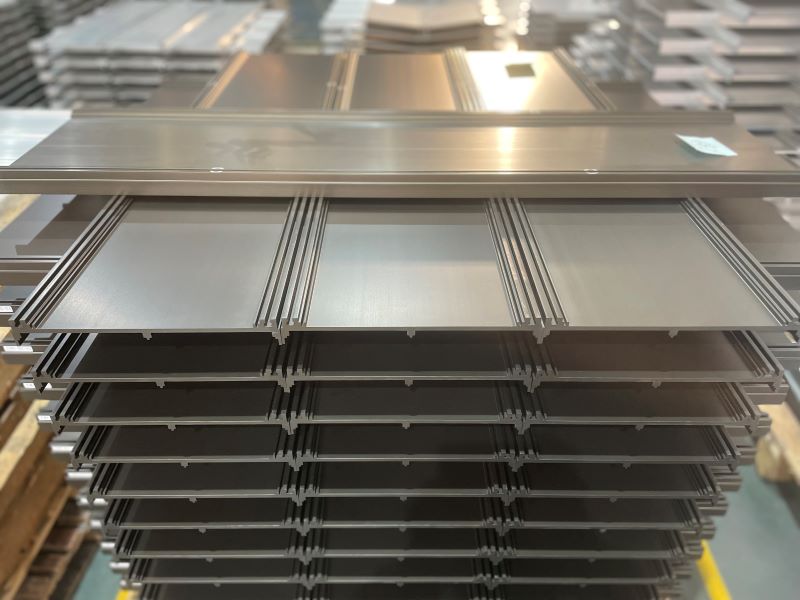

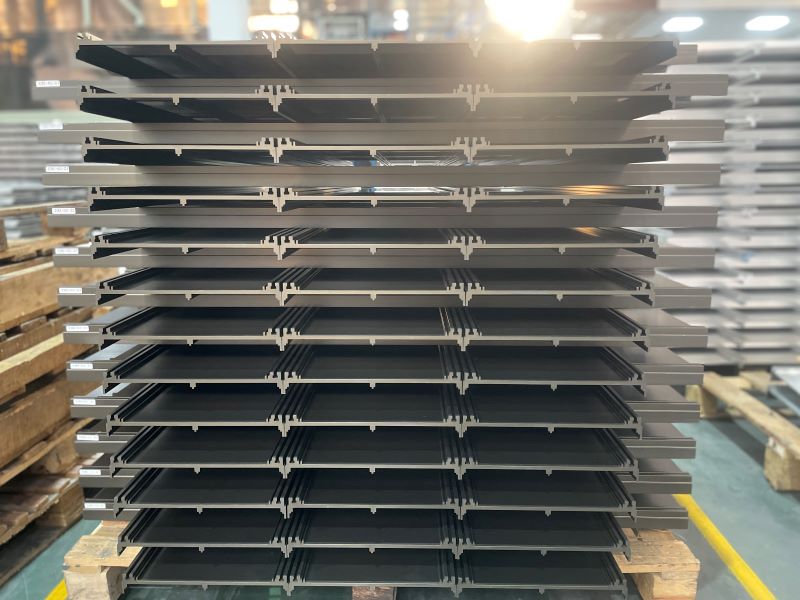

With 12 producing processes and 4 inspection processes,we are very proud of being the only supplier that can supply all type of Color Sorter parts chutes as a kind of Agriculture Machinery Parts with the top-rated materials and great performance to customers all over the world.

Your one-stop solution providing Agriculture Equipment Parts

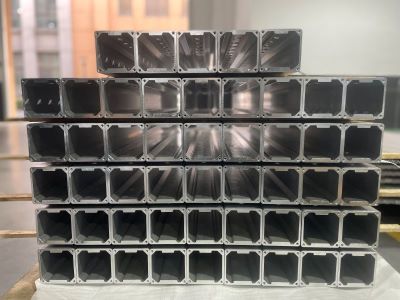

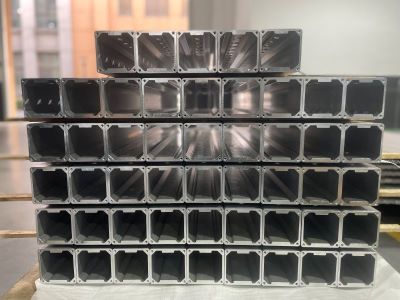

We have the advanced CNC equipment like 5-axis to manufacturing Agriculture Machinery Parts and the latest 4 anodizing lines to producing aluminum anodized Agriculture machinery parts.

All the precision machines and our rich experienced employee are ensured to meet your requirements of Agriculture machinery components,especially for Color Sorter Parts,Sorter Ejector Valve,Vibrating Feeder,Grain Elevator and more.

Here in Kezhen, the dimensions tolerance and surface quality of Agriculture Machinery Parts can be accurately controlled perfectly through digital control technology,thus to achieve high precision, high efficiency and high reliability manufacturing.

Please contact us and we will be at your service 100% if you have any needs of Agriculture Machinery Parts.

Equipment for Agriculture Machinery Parts industry

Through over 20 years of purchasing equipment continuously, we have complete processing machines to meet your customized needs of Agriculture machinery parts , such as:

5- Axis CNC machines,

Oxidation production lines,

Micro machines,

Lathe machines.

Boring machines,

Milling machines,

Grinding machines,

Digital detection machines,

Sewage treatment equipment,

Perfect outsourced processing

Why Kezhen Agriculture Machinery Parts

Doing the work of the appearance assessment of raw materials, sizes test, flatness test, straightness test, anodizing test, roughness test and etc, we supply the top quality Agriculture Machinery Parts, such as Color Sorter parts,Sorter Ejector valve,Vibrating Feeder,Grain Elevator and more,100% through QA program supervised by the Chief Quality Officer. Continuously doing the job of raw materials purchase management, manufacturing processes optimization, staff training,etc, our sales prices can always keep competitive all over the world.

Here in Kezhen,you can ensure to get uniform and high-quality Agriculture Machine Parts.

Send us your inquiries today!

Agriculture Machinery Parts Materials Requirements

Agriculture Machinery Parts production requires a variety of materials, and we obey standard materials to meet your quality requirements

Aluminum (Al 6061,AI6063, Al7075, Al 6068, Al 6062, etc)

Stainless steel (SS304, SS316, etc.)

Carbon steel(S55C,etc)

Copper

Titanium

Other alloy materials

1. Anodizing tank setup: The electrolytic cell is responsible for the entire electrolysis process and it is where the aluminum and cathode are immersed in the electrolytic cell. The electrolytic cell is usually made of chemically resistant materials such as polypropylene, PVC or coated stainless steel. To fix the anodes, the electrolytic cell comprises a rack mechanism which is further connected to the electrical busbar for a uniform and controllable power supply. On the other hand, a separate fixture holds the cathode and is connected to the busbar. During the anodizing tank setup, you need to consider different factors; the size of the tank, the busbar capacity and its safe connection to the rack, the cathode to anode area ratio (1:1 or 1:3), the filtration of electrolyte impurities, etc.

2. Control of acidic solution: The temperature and concentration of the acidic solution directly affect the thickness and quality of the anodized layer. High acid concentration may lead to faster layer growth, but will result in a rougher or burned surface. Therefore, you need to monitor the pH value of the solution. If any changes occur, you can add buffer solution or neutralizing solution according to the standard pH value set for the process.

3. Manage anodized layer and thickness: The anodized layer is formed when oxygen ions in the electrolyte migrate to the metal surface and react with metal atoms. Therefore, layer growth and thickness fundamentally depend on factors that affect the metal and oxygen ion concentrations. For example, temperature, current density, time, acid concentration, etc. Therefore, you must set all processing parameters taking into account thickness requirements and other surface finish characteristics.

4. Anodizing Tank Maintenance: As anodizing progresses, the bath begins to accumulate impurities such as metal salt residues and dissolved chemicals. In addition, metal ion concentrations tend to be higher than standard levels (ideally less than 20 g/L). These impurities affect process efficiency and overall quality. Therefore, filtering impurities and maintaining pH, proper agitation, and ion concentration are critical.

1. Preparation and cleaning: A uniform and smooth surface is essential for the application of the anodized layer. You can achieve this through mechanical treatment and chemical cleaning. Mechanical surface treatment such as grinding and polishing that remove surface irregularities and defects. While alkaline or acid cleaning removes grease, oil, dirt and any other contaminants, followed by rinsing with deionized water to remove residual cleaning agents. Therefore, etching can be further cleaned to peel off the thin surface layer and create a uniform matte effect.

2. Electrochemical process: The part to be anodized next becomes the anode, and the other highly conductive metal becomes the cathode, and both are immersed in the electrolytic cell. When current flows through this electrolytic device, the anode oxidizes and loses electrons. During the electrolysis process, the metal surface is oxidized to form a dense oxide film. This oxide film is very hard and can protect the metal from further corrosion.

3. Coloring (optional): After the oxide film is formed, it can be dyed to give the metal surface a different color.

4. Sealing: The corrosion resistance and wear resistance of the oxide film can be further enhanced by sealing.

Anodizing is a surface treatment method that forms a thin protective oxide layer on the surface of the substrate through an electrochemical process to achieve a smooth and uniform surface treatment, with a roughness value (Ra) as low as 0.5µm. Anodizing can improve the firmness, corrosion resistance, wear resistance and aesthetics of aluminum alloy, magnesium alloy and titanium alloy accessories.

Anodizing has a wide range of applications and is widely used in various industries such as medical devices, electronic communications, automotive accessories, aerospace, agricultural machinery, etc.

1000:1050,1070 Aluminum

Properties:High purity aluminum, electrical conductivity, thermal conductivity, corrosion resistance.

Application:Conductive materials, heat exchange devices, chemical equipment piping

2000:2011、2014 2017、2117 2024 Aluminum

Properties:Excellent machinability, high strength, low corrosion resistance

Application: Duralumin is a general term for cutting materials, structural materials such as parts and screws, aircraft materials, forging materials, automobile and motorcycle hydraulic parts, and sporting goods.

3000:3003、3203 Aluminum

Properties:Better heat resistance than pure aluminum, high strength, good corrosion resistance.

Application:Chemical equipment piping, heat exchange equipment, photosensitive cylinder for copy machines.

4000:4032 Aluminum

Properties:Good heat resistance and wear resistance

Application:VCR magnetic head, piston components, forging.

5000:5052,5056 Aluminum

Properties:Medium strength, corrosion resistance, good weld ability

Application:Chemical industry piping, machine parts, camera lens barrels.

6001 Aluminum

Properties:Medium-strength structural Aluminum

alloy with excellent corrosion resistance, weldability, and good processability

Application:Vehicles, ships, marine transport equipment, road materials and building materials, sports equipment, etc.

6003 Aluminum

Properties:Corrosion resistance, good surface treatment, excellent extrusion properties for most of the extruded materials

Application:Building materials, construction materials, decorative materials, home appliance materials and other general products.

7003 Aluminum

Medium strength structural Aluminum alloy for welding vehicles, automotive, locomotive parts

7005 Aluminum

Properties:Super duralumin, the highest strength alloy, corrosion resistant, weldable high strength material.

Application: Aircraft and other mechanical parts, sports equipment, etc.

9000 Aluminum

High-performance Aluminum alloys, with the addition of special elements (such as rare earth elements, etc.), have superb performance or certain special properties.

Newsletter Signu

Sign Up for Exclusive Offers From Us