Apr 18, 2025

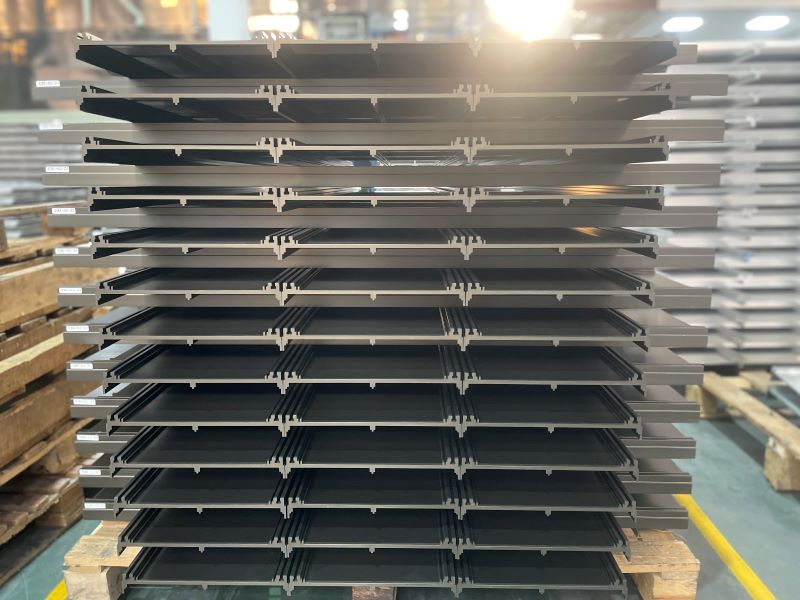

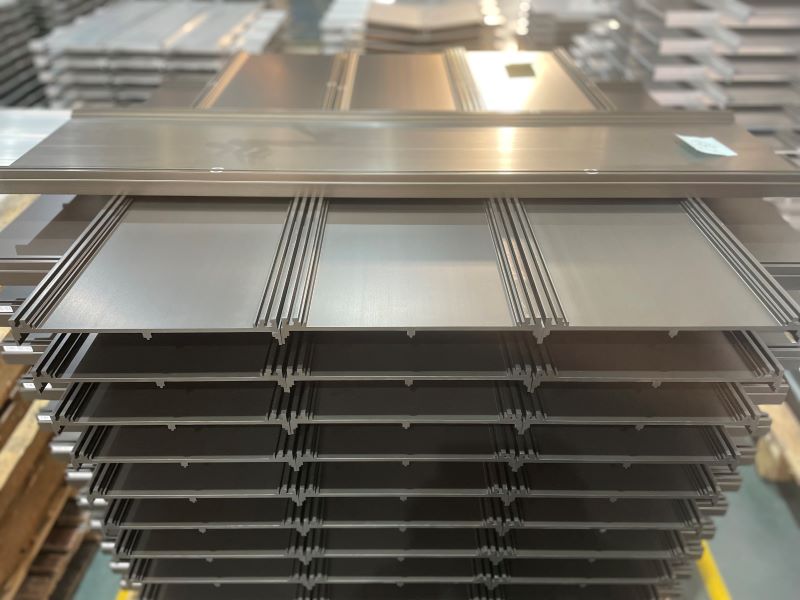

Anodizing is a surface treatment method that forms a thin protective oxide layer on the surface of the substrate through an electrochemical process to achieve a smooth and uniform surface treatment, with a roughness value (Ra) as low as 0.5µm. Anodizing can improve the firmness, corrosion resistance, wear resistance and aesthetics of aluminum alloy, magnesium alloy and titanium alloy accessories.

Anodizing has a wide range of applications and is widely used in various industries such as medical devices, electronic communications, automotive accessories, aerospace, agricultural machinery, etc.

Read More