Medical Machined Parts

The error tolerances of producing Medical Machined Parts are much higher than other industries, Kezhen have sets of precision machines to meet the requirements of high precision, high level cleanness,premium surface finish.

Your one-stop solution providing Medical CNC Machining

As a trusted manufacturer, we can offer the best quality Medical Machined Parts for wide range applications such as Prosthetic accessories,surgical devices parts,research equipment parts,OEC equipment components, CT/PET equipment components,Orthopedics equipment components, Dental equipment parts,and more.

Here in Kezhen, we produce Medical Machined Parts using the highest quality materials. Aluminum devices are often utilized for orthopedic, endoscopic, spinal, trauma and surgical scenarios.A wide range of medical-grade raw materials and more are carefully sourced to make the best quality Medical Parts Precision Machining,you can also guarantee a customized Medical Machined Parts that are tailored according to your specifications.

Send us your inquiries today!

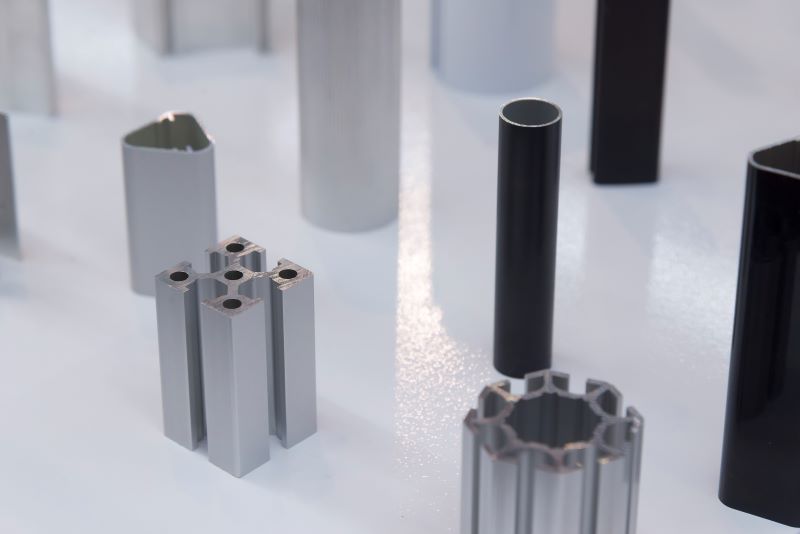

Equipment for Medical Machined Parts industry

Through over 20 years of purchasing equipment continuously, we have complete processing machines to meet your customized needs of Medical Parts Precision Machining, such as:

5- Axis CNC machines,

Oxidation production lines,

Micromachines,

Digital detection machines,

Sewage treatment equipment,

Perfect outsourced processing

Here in Kezhen, we produce Medical Parts Precision Machining using the highest quality materials. A wide range of medical-grade raw materials and more are carefully sourced to make the best quality Medical machined parts for you.

As a trusted manufacturer of Medical machined parts, we can offer the best quality CNC medical parts for wide range applications such as Prosthetic accessories,surgical devices parts,research equipment parts and more.

Kezhen have an extremely experienced team of machinists and engineers to ensure the continuation of great precision and tight tolerances. All medical accessories undergo comprehensive inspection methods to meed standards, requirements and customization.

Here in Kezhen,you can ensure to get uniform and high-quality Medical machined parts.

Send us your inquiries today!

The error tolerance of producing Medical Parts Precision Machining is much higher than other industries, Kezhen have sets of precision machines to meet the requirements.

High precision. We manufacture some Medical Parts Precision Machining require even 0.001-mm tight tolerance, due to their small sizes,some accessories need to be inserted into human body.

High level cleanness. Devices in the medical industry are contacted with human body, so the medical accessories require high level cleanness, Kezhen always maintain production cleanliness to meet your requirements of cleanness.

Premium surface finish. Kezhen has 4 anodizing lines, which can meed different surface treatment requirements. CNC medical parts require special surface treatment to cope with harsh application environments.

As a transnational purchaser of medical machined parts processing, you need to pay attention to several aspects to ensure the objectivity and correctness of the purchasing decision-making process.

1.Experience and expertise: Choose manufacturers with rich experience and expertise, especially those with professional knowledge of the medical device industry for the required parts processing.

2. Equipment and technology: Understand the processing equipment and technology used by the manufacturer to ensure that it is at an advanced level and to ensure that the medical machined parts produced are accurate and reliable.

3. Material selection: Ensure that the manufacturer can handle the various materials required for medical devices, understand the material properties and have high-quality material certification to meet the specific requirements of the product.

4. Customization capabilities: If customized medical machined parts are required, choose a supplier with strong design and customization capabilities to meet personalized product needs.

5. Supply chain stability: Evaluate the manufacturer's supply chain stability to ensure that it can guarantee timely delivery of parts and avoid production and transportation delays.

6. Customer reviews and reputation: Check the supplier's customer reviews and reputation to understand its reputation in the industry and customer satisfaction, which is one of the important references for selecting a manufacturer.

7.Sustainability: Consider the manufacturer's sustainability and long-term cooperation potential, and be able to establish a stable cooperative relationship to jointly promote the continuous optimization and improvement of products.

8. Communication and service: Establish good communication with the supplier and understand its service level, including pre-sales consultation, after-sales service and technical support, to ensure pleasant and smooth cooperation.

1000:1050,1070 Aluminum

Properties:High purity aluminum, electrical conductivity, thermal conductivity, corrosion resistance.

Application:Conductive materials, heat exchange devices, chemical equipment piping

2000:2011、2014 2017、2117 2024 Aluminum

Properties:Excellent machinability, high strength, low corrosion resistance

Application: Duralumin is a general term for cutting materials, structural materials such as parts and screws, aircraft materials, forging materials, automobile and motorcycle hydraulic parts, and sporting goods.

3000:3003、3203 Aluminum

Properties:Better heat resistance than pure aluminum, high strength, good corrosion resistance.

Application:Chemical equipment piping, heat exchange equipment, photosensitive cylinder for copy machines.

4000:4032 Aluminum

Properties:Good heat resistance and wear resistance

Application:VCR magnetic head, piston components, forging.

5000:5052,5056 Aluminum

Properties:Medium strength, corrosion resistance, good weld ability

Application:Chemical industry piping, machine parts, camera lens barrels.

6001 Aluminum

Properties:Medium-strength structural Aluminum

alloy with excellent corrosion resistance, weldability, and good processability

Application:Vehicles, ships, marine transport equipment, road materials and building materials, sports equipment, etc.

6003 Aluminum

Properties:Corrosion resistance, good surface treatment, excellent extrusion properties for most of the extruded materials

Application:Building materials, construction materials, decorative materials, home appliance materials and other general products.

7003 Aluminum

Medium strength structural Aluminum alloy for welding vehicles, automotive, locomotive parts

7005 Aluminum

Properties:Super duralumin, the highest strength alloy, corrosion resistant, weldable high strength material.

Application: Aircraft and other mechanical parts, sports equipment, etc.

9000 Aluminum

High-performance Aluminum alloys, with the addition of special elements (such as rare earth elements, etc.), have superb performance or certain special properties.

Newsletter Signu

Sign Up for Exclusive Offers From Us